Laser processing products and services

Product Description

"Laser carving products

Laser engraving is a process of electroplating surface treatment,

In the need to process the printing or pattern, and the like, through the laser beam of light can lead to surface physical and chemical changes in the material and engraved traces, or by burning some of the light material, showing the required etching pattern, Text.

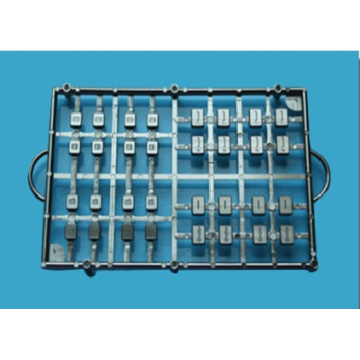

Jinyuan Kang company currently has high-power laser carving more than 10 Taiwan, 3D laser carving machine 4, with intelligent robot arm to the product in all directions, multi-angle processing to meet customer needs, the system features:

● good stability

laser engraving machine laser source using high-power semiconductor matrix, greatly extending the product life and system stability.

● high precision

Laser Engraving Machine Laser Marking system output beam quality closer to the ideal mode, more suitable for ultra-fine processing, the smallest character size up to 0.2mm, so that the accuracy of laser marking to a new order of magnitude.

Fast speed

Laser Engraving Machine laser marking system using ultra-fine optical devices, the galvanometer speed is much higher than the traditional laser system.

● Low energy consumption

Laser engraving machine laser marking system using high-performance semiconductor matrix, the laser conversion efficiency greatly improved.

● High reliability

Laser engraving machine laser marking system of high system integration, do not need high-voltage power supply, high-voltage devices, greatly guarantee system reliability. Can be carved metal and a variety of non-metallic materials. More suitable for some applications require more sophisticated, more accurate occasions. Used in electronic components, integrated circuits (IC), electrical appliances, mobile communications, metal products, tool accessories, precision instruments, glasses watches and clocks, jewelry accessories, auto parts, plastic keys, building materials, PVC pipe, medical equipment and other industries.

Suitable materials include: ordinary metals and alloys (iron, copper, aluminum, magnesium, zinc and all other metals), rare metals and alloys (gold, silver, titanium), metal oxides (all kinds of metal oxides can be), special surface (Phosphor, aluminum anodized, electroplated surface), ABS material (electrical appliances shell, daily necessities), ink (light button, printed products), epoxy resin (electronic components of the package, insulation). "

Product Categories : Laser Process